Versatile Connectivity

Creating Extra Space for Enhanced Functionality

Extender backshells are specialized connector accessories designed to provide additional space between a connector and its strain relief. These components are crucial for applications requiring extra room for service loops, resistors, re-termination, or other wiring needs. Key features include:

Extended Length: Typically 1.50 inches, with options for custom lengths in 0.25-inch increments.

Connector Replication: The accessory threads and teeth of the original connector are replicated on the back end of the extender, ensuring compatibility and proper mating.

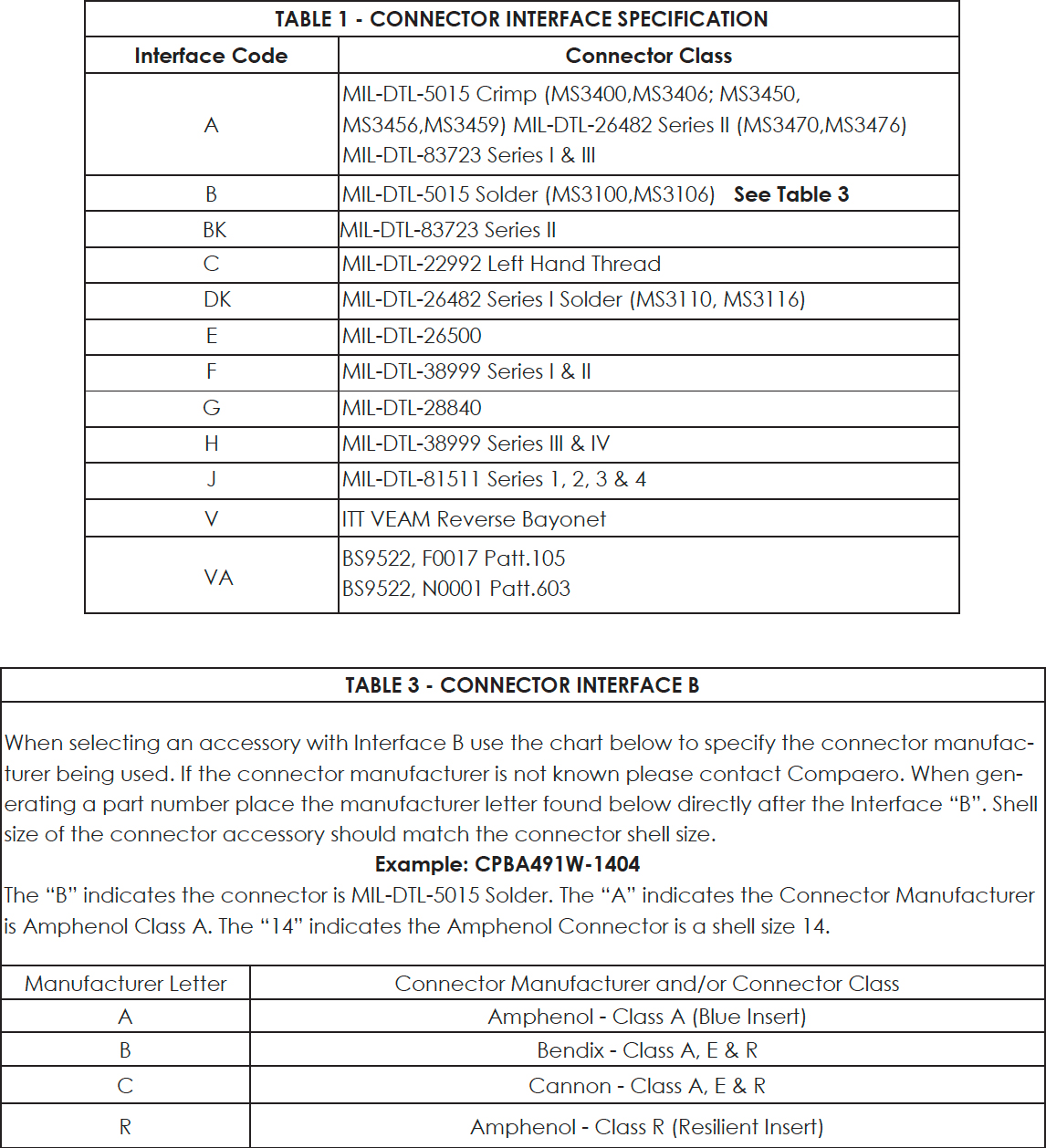

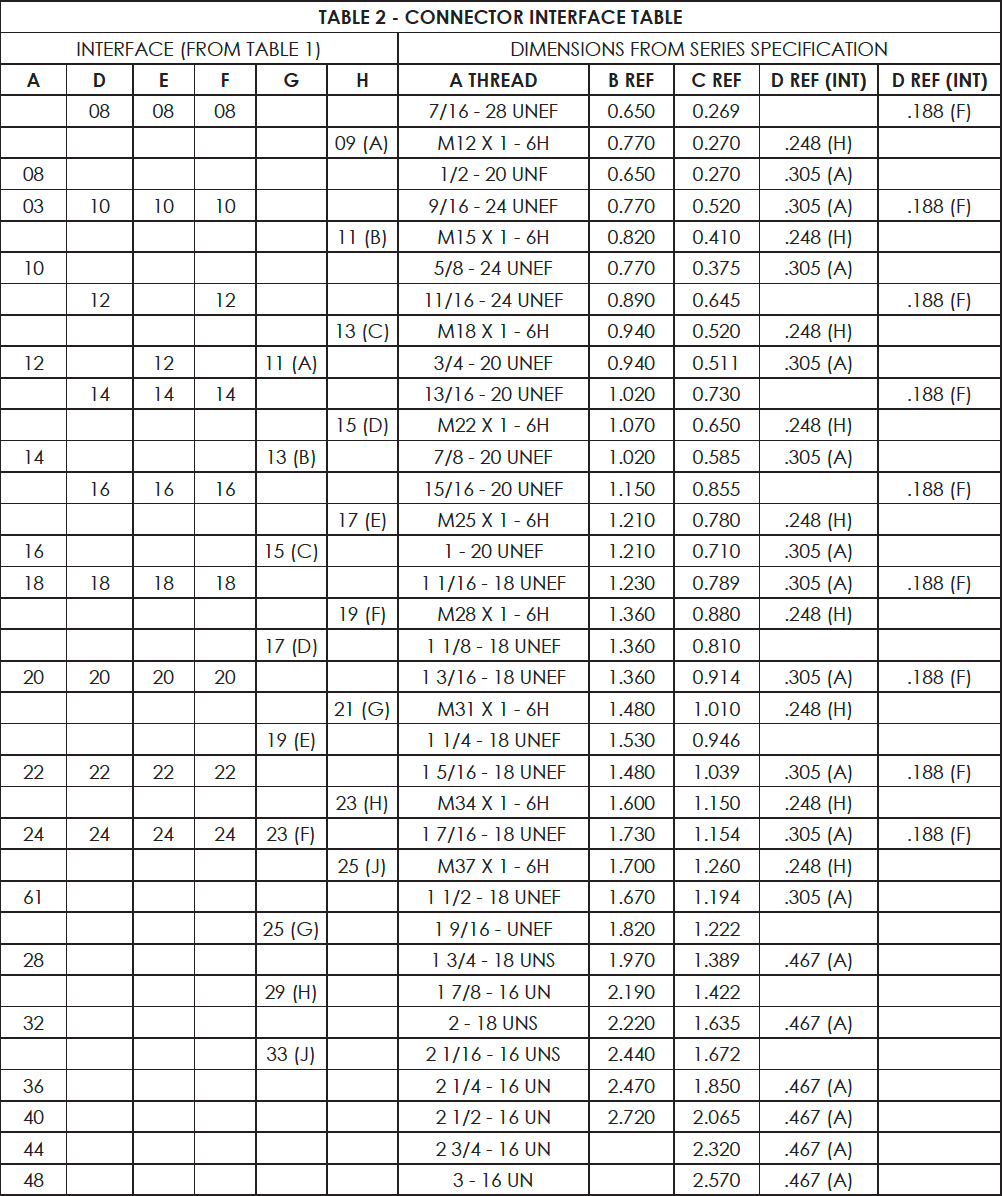

Versatility: Available for various connector interfaces, including MIL-DTL-38999, MIL-DTL-5015, and others.

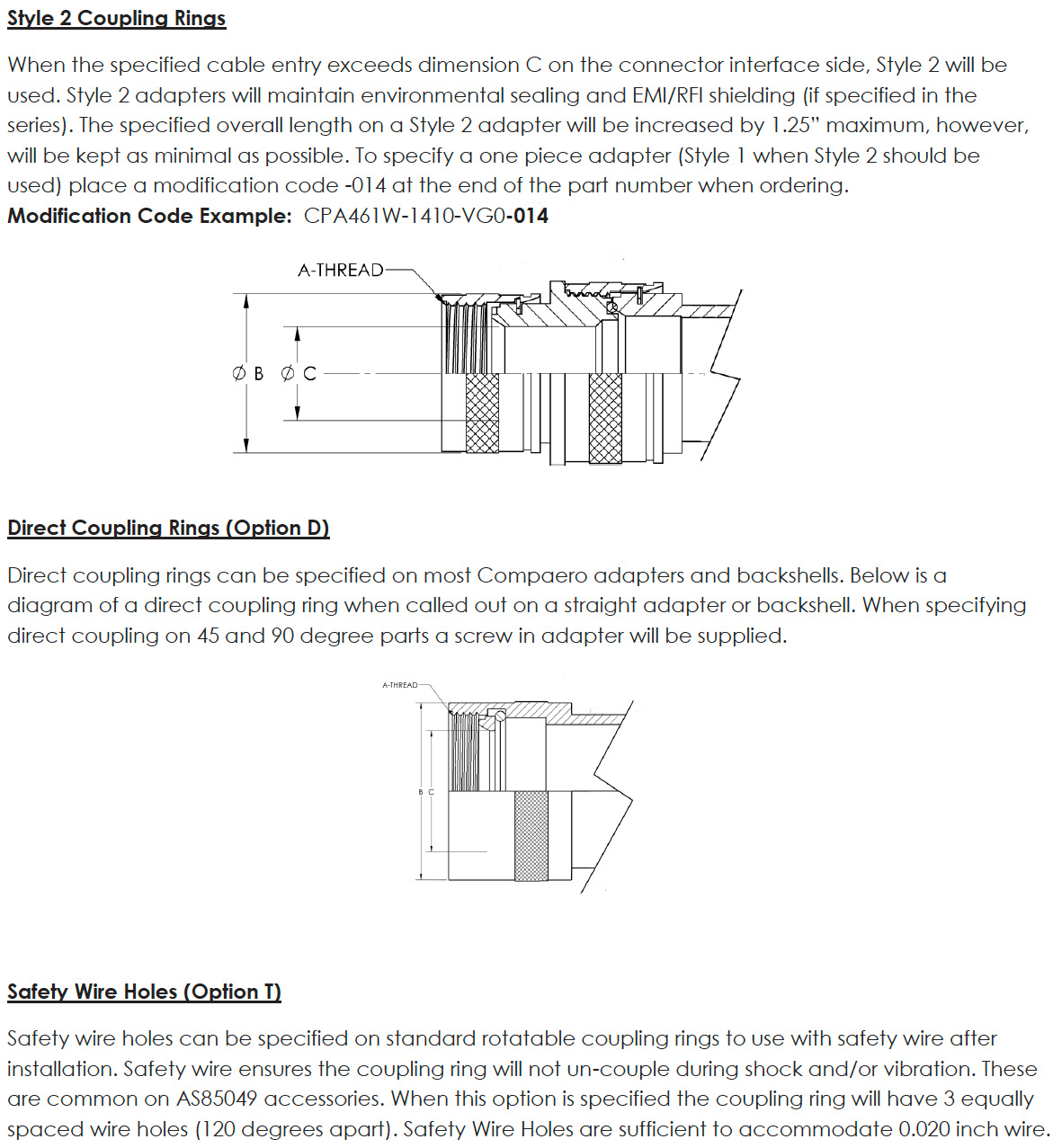

Multiple Options: Offered in straight configurations with various coupling ring options such as standard rotatable, direct coupling, self-locking, and safety wire holes.

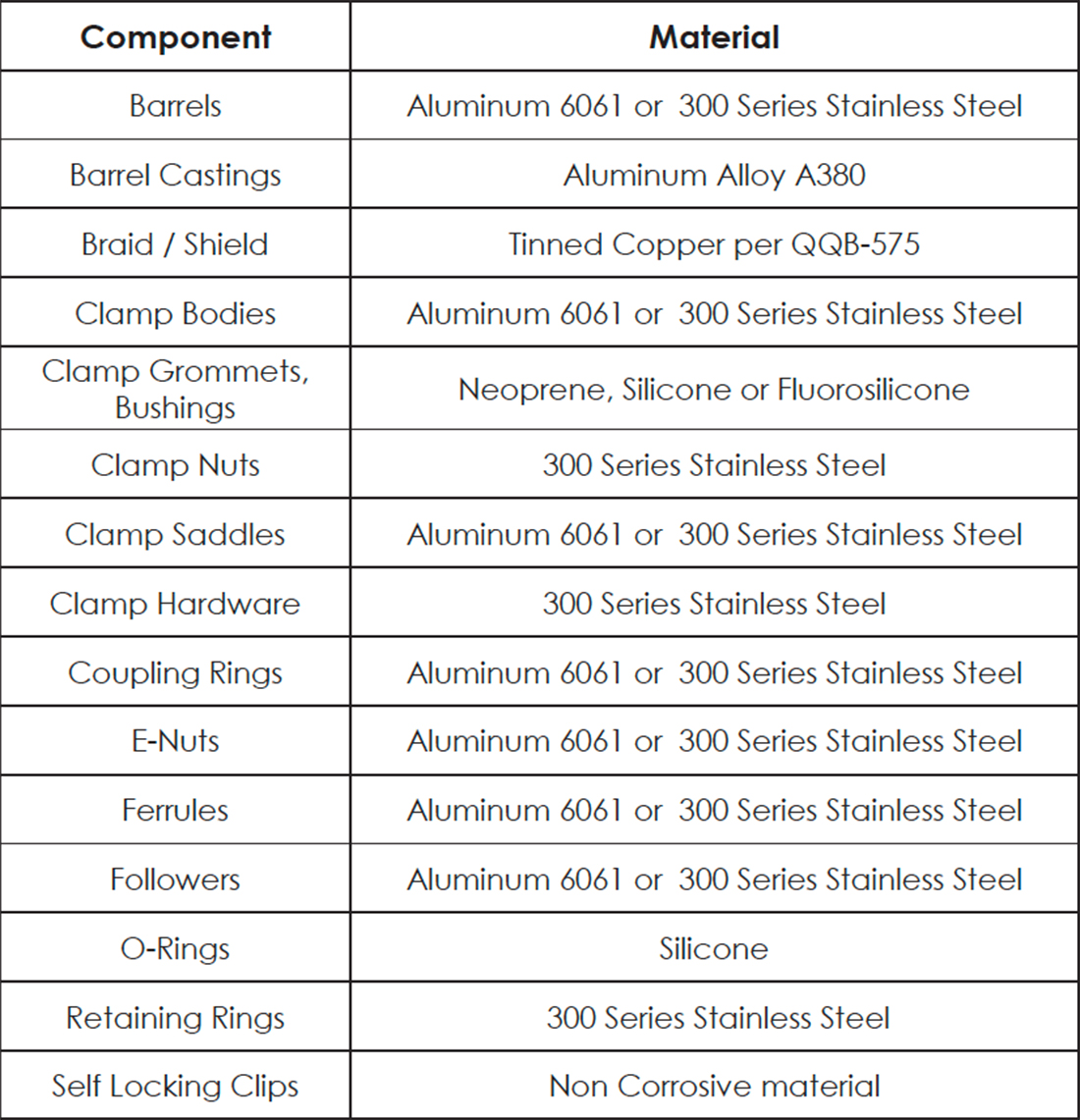

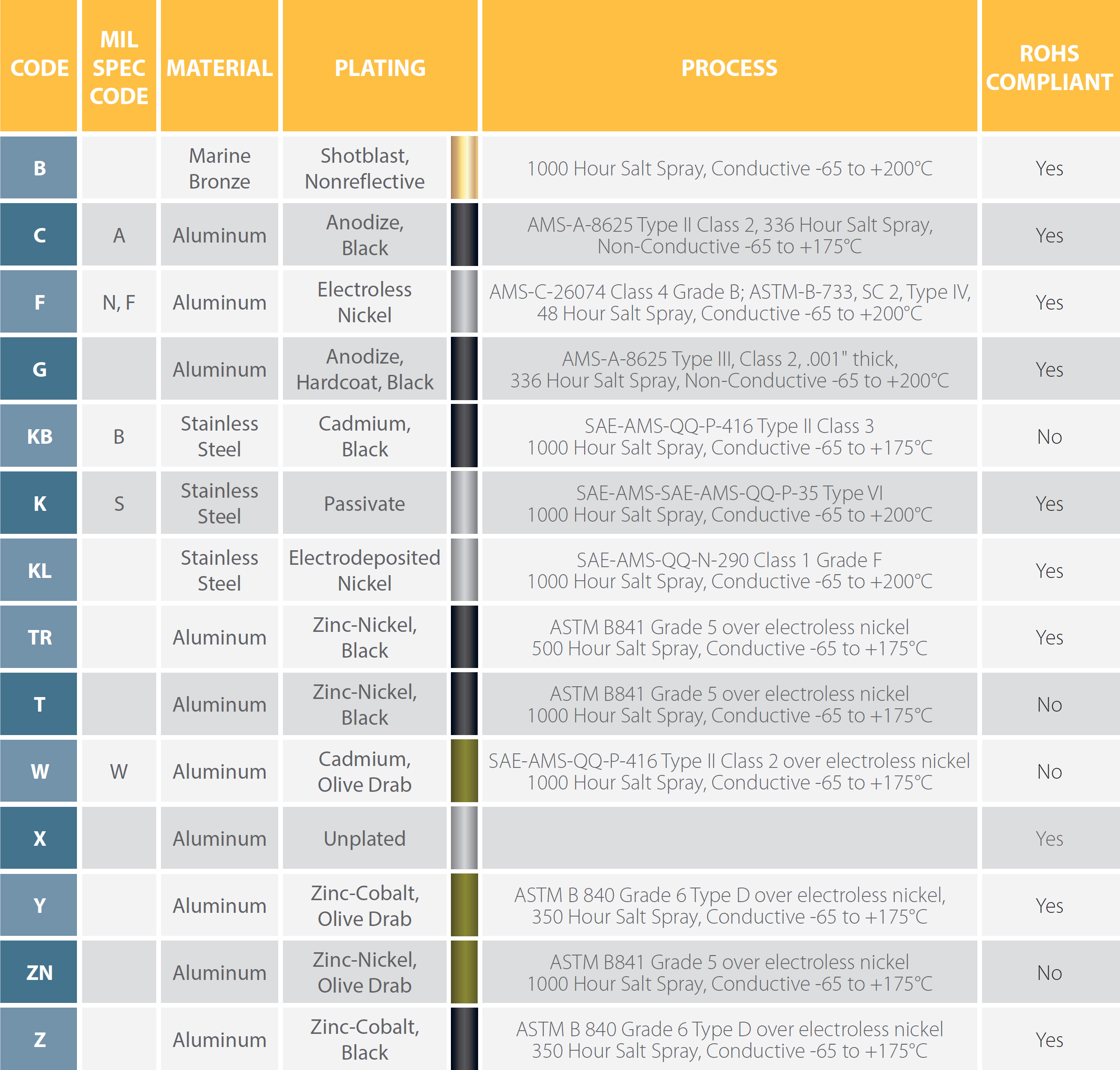

Material Choices: Manufactured in materials like aluminum or stainless steel with different finishes for environmental protection.

Customization: Can be ordered with specific shell sizes, lengths, and coupling ring options to meet exact application requirements.

These extender backshells are ideal for applications where additional wiring space is needed without compromising the connector’s original mating interface or environmental sealing properties. They are commonly used in aerospace, defense, and other high-performance electronic systems where space constraints and reliability are critical factors.

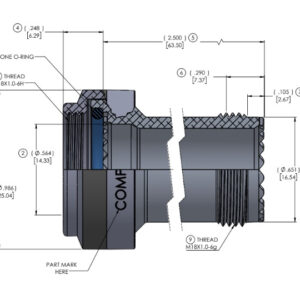

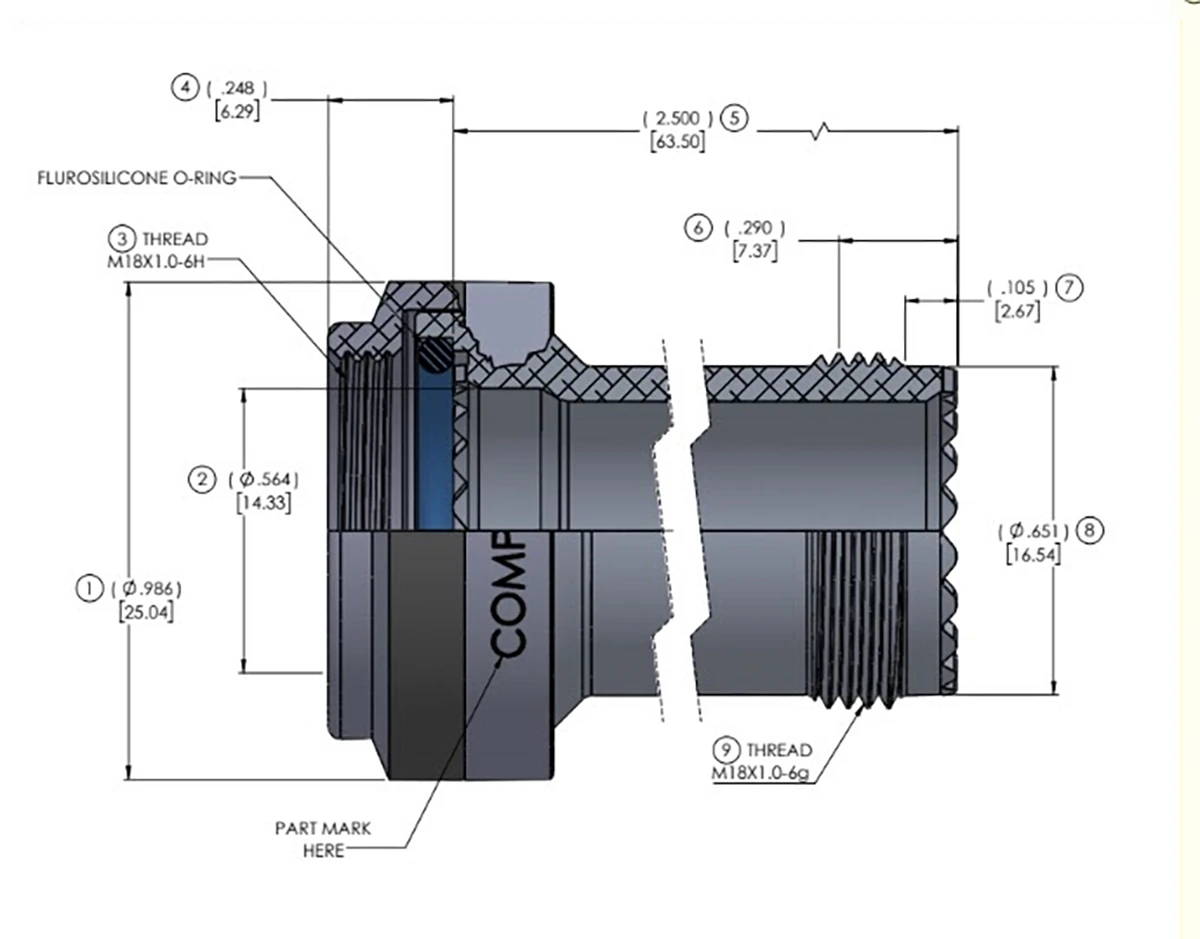

Series 38 Extender Backshells provide extra room behind a connector and in front of a strain relief to allow for service loops, resistors, re-termination or other needs. The accessory threads and teeth of the connector are replicated on the back end of the Extender Backshell.

Notes:

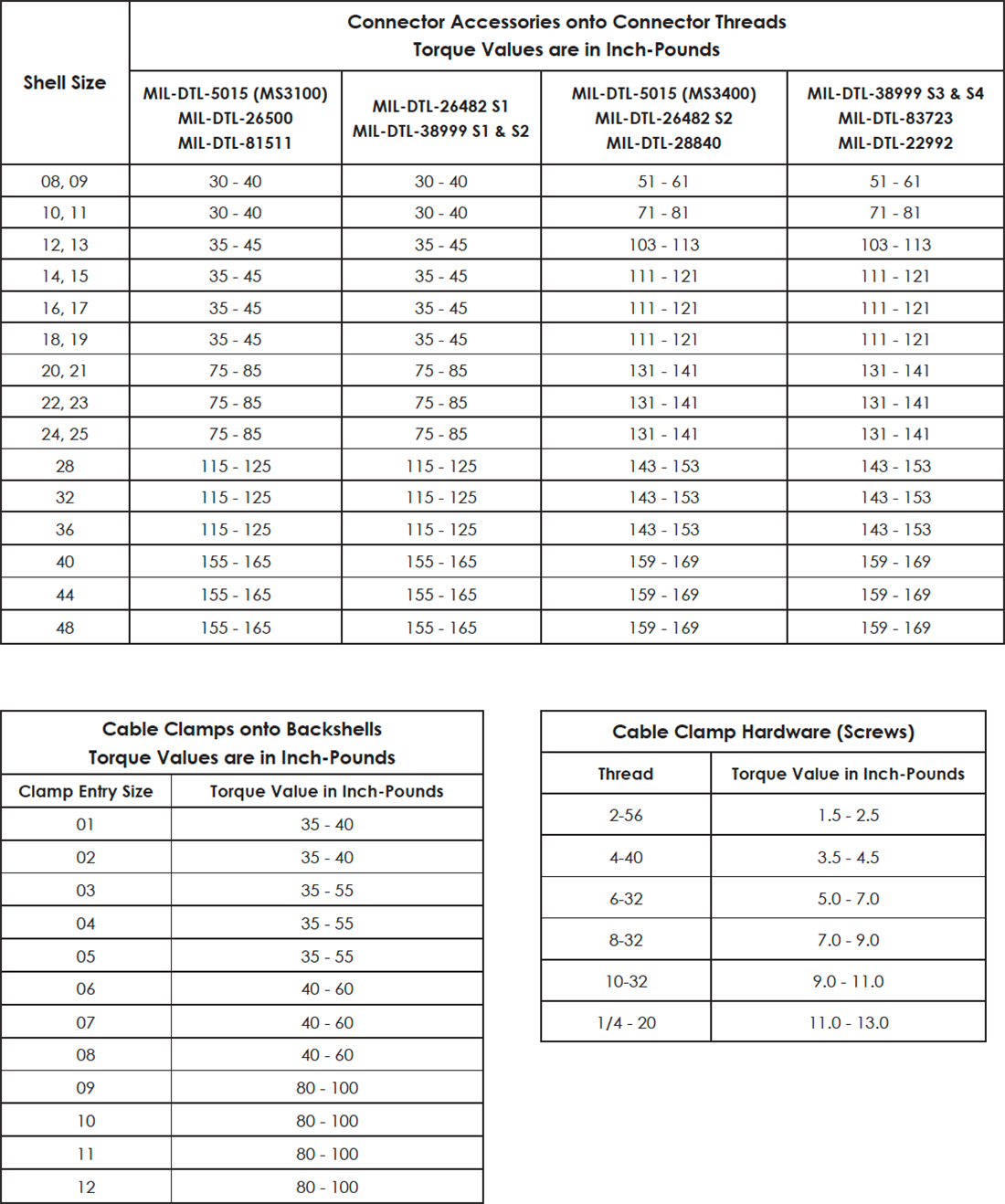

1. All dimensions are in Inches 2. See Section G for torque information

3. Because the rear grommet on some connectors is crucial to environmental sealing, the environmental suitability of this series must be determined by the user.

4. Length on straight backshells will be 1.50” unless otherwise specified in part number